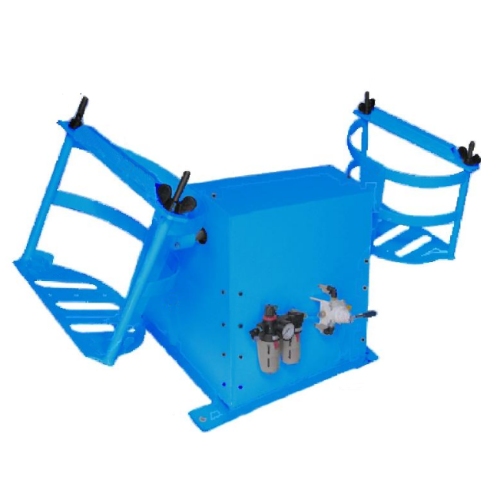

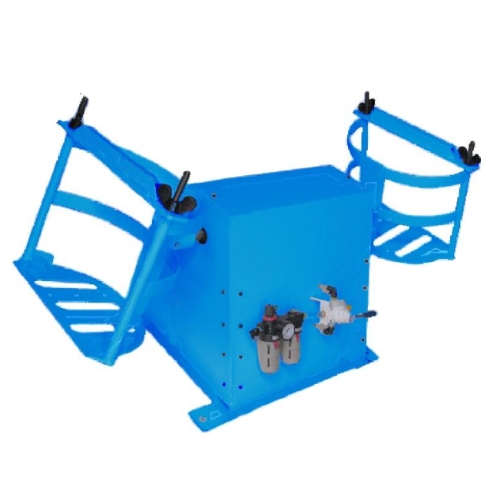

5 Gallon Double Can Tumbler

Specis for Model DT-D5, 5 Gallon Double Can Tumbler:

Industrial Can & Pail Mixer for Paint, Coating, Adhesive, and Chemical Applications

The DrumTumbler manufactures DT-D5 model is designed for efficient and safe mixing of materials directly

inside sealed cans or pails. It enables users to re-homogenize, blend, without opening containers—idealfor reducing contamination and cleanup time.

Technical Specifications:

| Specification | Details |

|---|---|

| Model | DT-D5 |

| Motor Power | 1 HP, single-phase, 220V, 50Hz |

| Mixing Capacity | ONE or TWO cans at a time |

| Rotation Speed | Up to 50 RPM (continuous rotation, one direction) |

| Timer | Adjustable 1–60 minutes |

| Compatible Container Sizes | 4.5" – 16.5" (114 – 419 mm) tall, up to 12.5" (317.5 mm) diameter |

| Optional Extra-Large Can Holder (XLC) | Accepts cans up to 16" (406 mm) diameter, 11" – 22" (279 – 559 mm) tall |

| Typical Container Type | 5-gallon (19 – 20 L) steel can or plastic pail |

| Safety Enclosure Kit | GEK-2-305-1 (sold separately, includes interlock switch) |

| Compliance Requirements | OSHA / CSA / EU standards require use of enclosure with interlock |

Key Features:

1)Efficiently mixes and re-homogenizes materials inside 1–5 gallon drums.

2)Works with steel, plastic, or fiber containers (5–20 liters).

3)Ideal for restoring settled ingredients and producing uniform batches.

4)Can tumble parts with media for polishing or surface finishing.

5)Meets OSHA safety standards—use with enclosure and interlock system.

Ideal Applications:

Paints, Coatings & Colorants:

1)Mixing automotive refinish paint or 2K polyurethane coatings inside 5-gallon pails

2)Re-dispersing industrial primers, PU varnishes, or marine coatings before use

3)Re-homogenizing water-based latex paint or epoxy floor coatings that have settled

4)Blending pigment pastes and color concentrates for tinting systems

Adhesives, Sealants & Glues:

1)Agitating epoxy resin + hardener components before dispensing

2)Re-mixing silicone sealants or PU sealant compounds after storage

3)Tumbling PVA white glue, contact cement, or rubber adhesive to restore consistency

4)Mixing cyanoacrylate base adhesive (super glue) before filling operations

Inks & Pigments:

1)Blending UV-curable inks, offset printing inks, or gravure inks

2)Mixing screen printing emulsions and solvent-based pigment dispersions

3)Restoring carbon black, TiO₂, or metallic pigment suspensions for uniform viscosity

4)Tumbling toner powders or liquid conductive inks in closed containers

Resins, Polymers & Catalysts:

1)Re-homogenizing unsaturated polyester resin (UPR) or epoxy systems before batching

2)Mixing hardener-catalyst blends such as MEKP with prepolymer resin

3)Blending acrylic polymer emulsions, phenolic resins, or PU prepolymers

4)Pre-conditioning silicone RTV base with crosslinker prior to application

Chemical, Cleaning & Maintenance Materials:

1)Mixing detergent pastes, industrial cleaners, or degreasing solutions

2)Agitating wax emulsions, polish creams, or lubricant dispersions

3)Blending rust inhibitors, anti-corrosion coatings, or protective oils

Specialty & Laboratory Applications:

1)Pre-mixing silica slurries, ceramic suspensions, or alumina polishing paste

2)Blending cosmetic creams, pigmented lotions, or nail gel bases

3)Agitating biochemical reagents or polymer test samples before laboratory analysis

4)Tumbling graphite, CNT, or metal oxide powders for advanced material R&D

Packing method:

1)Inside with film packaging

2)Outside with wooden case