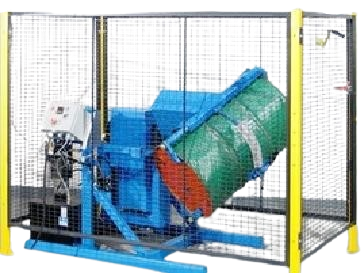

Customized Drum/Pail Tumbler

Custom Drum Tumblers | Tailor-Made Mixing Solutions

Overview

DrumTumbler specializes in designing and manufacturing customized drum tumblers to meet each customer’s specific process requirements.

From standard oil drum mixers to fully engineered closed-drum mixing systems, we provide safe, efficient, and application-oriented solutions for the chemical, coating, adhesive, resin, ink, and oilfield industries.

Our engineering team develops every drum tumbler with precision and flexibility — whether your goal is re-homogenizing settled materials, improving batch consistency, or ensuring explosion-proof safety in hazardous environments.

Why Choose Customization:

Every process is different. The viscosity of your materials, drum size, working environment, and local safety standards all affect how your mixer should perform.

A standard model might not fit your specific drum or production layout — which is why custom design ensures perfect performance, safety, and compliance with OSHA, CE, or ATEX standards.

Customization Capabilities:

Our drum mixers are engineered for a wide range of industrial applications.

Whether you need to blend, homogenize, or re-activate materials inside sealed drums, we can deliver the right solution — from standard oil drum mixers to fully customized barrel agitators.

Each DrumTumbler unit is tailor-designed to match your process, material characteristics, and production environment.

Our technical team works closely with every customer to ensure the final design achieves optimal safety, performance, and compatibility.

With an experienced engineering team, we can meet virtually any customization requirement — including:

Explosion-proof motors and control panels

Variable-speed or fixed-speed control

Single-drum or dual-drum configurations

Different drum sizes (30L – 200L) and materials (steel / L-ring plastic)

Pneumatic or hydraulic tilt systems

Safety enclosure with interlock and emergency stop

Optional heating, cooling, or vibration functions

Whatever your mixing requirement, DrumTumbler builds it to fit your process.

Industries Served:

Paints and coatings

Adhesives and sealants

Resins and catalysts

Inks and pigments

Chemical additives

Lubricants and greases

Battery slurry and conductive pastes

Oilfield and drilling fluids

How It Works:

Inquiry & Consultation – Share your process details, materials, and required drum size.

Design Proposal – Our engineers prepare technical drawings and performance parameters.

Approval & Production – Confirm design and start manufacturing.

Testing & Delivery – Each unit is tested before shipment.

After-Sales Support – Installation guidance and continuous service available worldwide.

Why DrumTumbler:

Over 15 years of manufacturing experience

Complete R&D and design capabilities

OSHA / CSA / CE / ATEX compliant safety designs

OEM / ODM available for private labeling

Fast response, stable delivery, and global support

Packing method:

1)Inside with film packaging

2)Outside with wooden case